- This topic is empty.

-

AuthorPosts

-

2025-02-13 at 18:33 #119183

In the industrial landscape, vertical mill tables play a pivotal role in various manufacturing and processing sectors. These robust components are integral to the functioning of vertical mills, which are widely used in cement production, mineral processing, and other heavy industries. This blog article delves into the key features and benefits of vertical mill tables.

Understanding Vertical Mill Tables

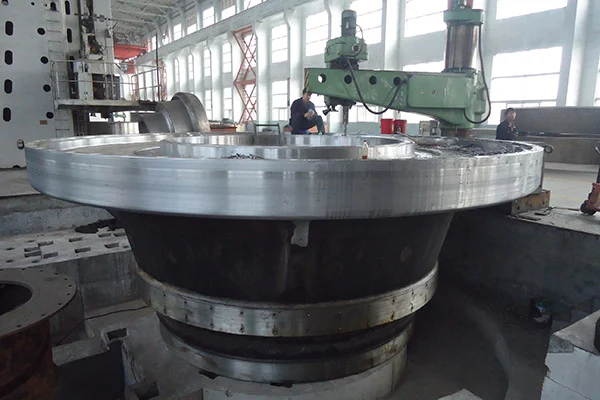

Vertical mill tables are essentially the workhorse of vertical mills. They are designed to withstand the rigorous demands of grinding and milling operations. These tables are subjected to immense forces and need to maintain precision and durability to ensure the efficient production of materials such as cement, minerals, and other industrial products.

Key Features of Vertical Mill Tables

1. Customizability

One of the features of vertical mill tables is their customizability. Shanghai Special Metal Co., Ltd offers a wide range of customized mill tables, including all types of GRM series vertical mill tables and other brands/models. This flexibility allows clients to tailor the mill tables to their specific requirements, ensuring optimal performance in their unique operational environments.

2. Material Quality

The main materials used in the construction of these mill tables are plain carbon steel and Si-Mn steel. These materials are chosen for their strength, durability, and resistance to wear and tear. The use of high-quality steel ensures that the mill tables can withstand the heavy loads and continuous operation without compromising on performance.

3. Advanced Casting Technology

Shanghai Special Metal Co., Ltd has optimized the casting technology of mill tables by applying the most advanced sodium silicate-bonded sand molding. This technology overcomes the structural shortcomings of traditional methods, resulting in a mill table base that is uniformly stressed. The nip angle between the mill table and mill roller is enlarged, and the non-wear-resisting face has excellent anti-corrosion properties.

4. Precision Engineering

The production process of vertical mill tables is meticulous and involves several stages, including wooden pattern production, molding, pouring, first cleaning, heat treatment, grinding, inspection, rough machining, finishing machining, and finally, packing and delivery. Each step is carefully monitored to ensure the highest standards of quality and precision.

5. Quality Assurance

The fabrication route of these mill tables is governed by the provisions of the implemented Quality System ISO 9001: 2000. This ensures full traceability of every process step. The company provides manufacturer test certificates according to DIN EN 10.204 § 3.1, which include chemical composition, mechanical properties, and non-destructive examination. Dimensional checks are supported with an “as-built” sketch, and records of the heat treatment chart are maintained.

Benefits of Vertical Mill Tables

1. High Hardness and Wear Resistance

The high hardness and wear-resistant properties of vertical mill tables are crucial for their longevity and performance. These tables are designed to resist cracking and wear, ensuring that they can operate efficiently over extended periods without the need for frequent replacements.

2. Superior Finishing Techniques

Arc air gouging and shot blasting are used in the finishing of casting steels, ensuring a good appearance quality. This not only enhances the aesthetic appeal of the mill tables but also contributes to their overall durability and resistance to corrosion.

3. Non-Destructive Examination (NDE)

Before delivery, NDE inspections are applied to the stress surfaces of the mill tables. This ensures that the products have good stress capability and are stable in operation. The use of NDE techniques helps in identifying any potential flaws or weaknesses in the structure, thereby ensuring the reliability and safety of the mill tables.

4. Wide Range of A

pplications

Vertical mill tables are applicable in a variety of industries, including cement, building materials, chemicals, coal, electricity, metallurgy, and non-metallic mines. Their versatility makes them an essential component in the production processes of these sectors, contributing to the efficient and effective operation of vertical mills.

5. Market Acceptance

The products from Shanghai Special Metal Co., Ltd, including vertical mill rollers, mill tables, hollow shafts, large ring gears, and riding wheels, are well accepted by the overseas market.

Conclusion

Vertical mill tables are indispensable components in the industrial sector, particularly in the manufacturing and processing of materials. The key features and benefits outlined above highlight the importance of these tables in ensuring the smooth and efficient operation of vertical mills. As industries continue to evolve and demand more from their equipment, the role of vertical mill tables will remain crucial in driving productivity and efficiency.

China Special Metal Group Limited (CSM), a supplier of steel casting for metallurgical machinery, cement & mining machinery, building material machinery, ceramic industry, forging industry, shipbuilding industry and chemical industry, is dedicated to offering high-quality of steel casting, high-precision machining products and welded fabrications to valued customers all over the world.

If you are looking for vertical mill tables solutions or related technical support, welcome to contact us.

E-mail:sales@special-metal.com

http://www.special-metal.com

China Special Metal Group Limited (CSM) -

AuthorPosts

- You must be logged in to reply to this topic.